Calibration &

Testing Services

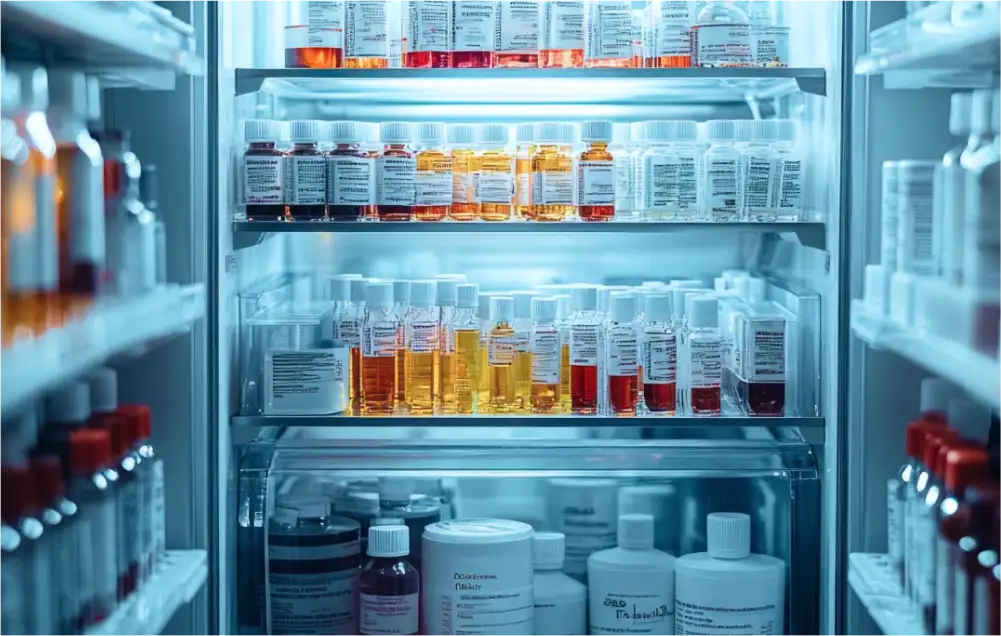

When the quality of medicines or food hinges on temperature, there’s no room for doubt. Scalesius offers precision calibration for thermal and humidity instruments building trust, audit readiness, and consistency into your operations.

01

What is Calibration

and Testing?

It’s the scientific process of verifying and adjusting instruments to ensure accurate, reliable measurements. In temperature-controlled logistics, this removes hidden risks and drives regulatory compliance.

How It

Helps You

- Satisfies ISO, WHO GDP, and local MOH & DM requirements.

- Prevents costly product spoilage and compliance breaches.

- Builds audit trails with full traceability.

- Boosts quality control and brand reputation.

- On-site and off-site services available designed around your schedules.

Frequently Asked Questions

Why is calibration important for cold chain equipment?

Calibration ensures instruments deliver accurate readings, helping maintain product integrity, meet industry standards, and avoid costly spoilage during storage or transport.

What equipment does Scalesius calibrate and test?

We handle calibration for refrigerators, freezers, data loggers, thermometers, and other critical cold chain instruments used in healthcare, logistics, and food sectors.

How often should calibration be performed?

Calibration frequency depends on equipment use and regulatory needs, but annual checks are recommended for most cold chain devices to maintain reliability and compliance.

How does Scalesius conduct calibration?

We use traceable standards and certified procedures to measure, adjust, and document performance, ensuring equipment accuracy and compliance with international quality guidelines.

Precision that protects

your compliance

Contact Scalesius to keep every instrument calibrated to perfection.